In the wake of unprecedented disruption, supply chains are redefining resilience through strategic investments and collaborative innovation.

The COVID-19 pandemic exposed vulnerabilities in global supply chains, revealing the fragility of tightly coupled sourcing strategies and lean inventories. Shortages of essential goods—from medical supplies to consumer electronics—prompted a collective reckoning across industries and government agencies.

By 2025, companies have moved beyond reactive firefighting toward a proactive stance, embedding resilience into core processes to withstand persistent challenges such as inflation and geopolitical tensions. High transportation costs, tariffs, and transport delays now rank among the top risks demanding sustained attention.

Firms face a complex trade-off between efficiency and robustness. After a temporary shift to high inventories, many are optimizing back to just-in-time models in stable regions, while retaining buffers in critical nodes. Detailed insights into cost structures are essential for this balancing act.

Organizations are leveraging detailed cost-to-serve analyses to dissect expenses by product, channel, and route. This granular approach uncovers hidden costs, informing strategic decisions about where to invest in capacity or redundancy.

Digital tools and advanced analytics lie at the heart of modern resilience strategies. Across industries, there is rapid acceleration in integration of AI for forecasting, monitoring, and automated decision-making. Manufacturers and distributors are channeling capital into platforms that yield predictive insights and real-time visibility.

By mid-2025, nearly 78% of manufacturers have integrated or plan to implement supply chain planning software, harnessing big data and machine learning. Supplier Relationship Management (SRM) systems and end-to-end visibility solutions are becoming standard, enabling risk flags before they escalate.

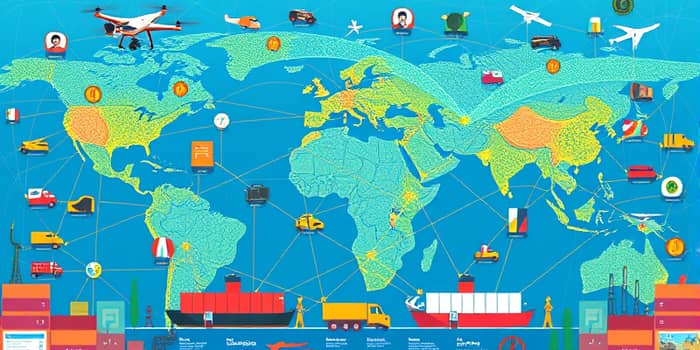

Supplier concentration once offered cost advantages, but recent shocks have driven more than 90% of U.S. companies to pursue diversification. Over 75% now embrace multi-region supplier models to reduce risk, blending near-shoring, on-shoring, and traditional far-shoring.

This multishoring approach enhances security but adds layers of complexity in coordination, compliance, and quality control. In response, leading firms are simplifying where possible, consolidating relationships with versatile partners and pursuing targeted mergers and acquisitions to strengthen capabilities.

Resilient supply chains employ rigorous risk assessment frameworks, moving beyond static audits to regular stress-testing and scenario simulations. These exercises reveal weaknesses under extreme conditions, from geopolitical flare-ups to natural disasters.

Despite widespread adoption of risk tools, only 21% of brands report feeling extremely confident in handling future disruptions. This confidence gap highlights a crucial area for investment in contingency planning and ongoing capability development.

The concept of a “Constellation of Value” underscores the power of secure and collaborative supply networks. By integrating suppliers, logistics providers, technology partners, and customers, firms foster shared resilience and spur innovation across the value chain.

At the policy level, stakeholders advocate for logistics friction reduction, regulatory convergence, and the creation of “industrial commons”—shared reserves of inventory and capacity for emergencies. Global coordination on these fronts can amplify the impact of national efforts.

Looking ahead, executives and policymakers can take concrete steps to embed resilience without sacrificing agility:

By pursuing these actions, organizations will not only navigate future disruptions but also unlock new opportunities for growth and innovation.

As supply chains stand at this critical inflection point, the choices made today will define competitiveness tomorrow. Embracing a balanced approach—where cost efficiency meets robust resilience—ensures businesses and economies can thrive in an uncertain world.

References